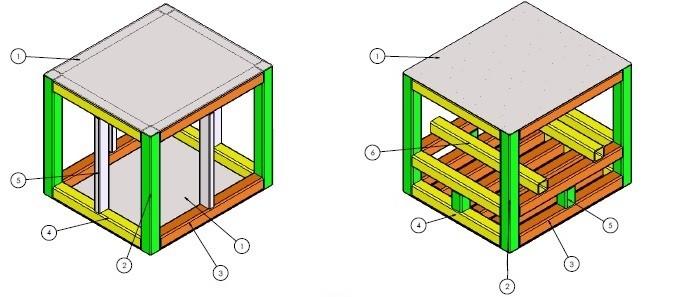

Bradbury recently won a contract to produce custom built steel cages to aid in test drops for the US Air Force. Three different sizes, colour and weight combinations have been specified to simulate the actual loads that they are testing for. The cages are being engineered with restraint points so that they can be attached to an air drop platform and a parachute, and then released from a C-130 aircraft. This is truly a joint effort by the Bradbury Group, as the cages are being engineered at our head office in Scunthorpe and built at our manufacturing facility in Scotland.

This is a ground-breaking venture for the Bradbury Group, showing how our products can be adapted and modified to suit a vast array of requirements.